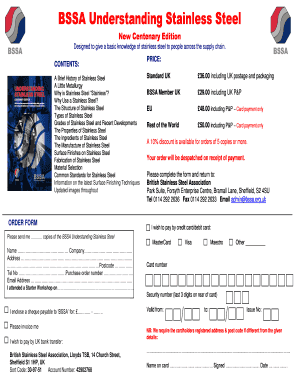

The BSSA. • Who we are! • What we do! • Stainless Steel. • Types and Structure. • Properties: mechanical, physical, corrosion resistance. marks the th anniversary of stainless steels. To mark this event, Alan Harrison of the British Stainless Steel Association (BSSA) has revised his popular . The BSSA Guide to Understanding Stainless Steel is now available to buy. Designed to give a basic knowledge of stainless steel to people.

| Author: | Zolodal Faer |

| Country: | New Zealand |

| Language: | English (Spanish) |

| Genre: | Environment |

| Published (Last): | 5 May 2010 |

| Pages: | 437 |

| PDF File Size: | 18.9 Mb |

| ePub File Size: | 2.11 Mb |

| ISBN: | 506-6-99285-543-2 |

| Downloads: | 3467 |

| Price: | Free* [*Free Regsitration Required] |

| Uploader: | Domuro |

This process removes contaminants and allows for a passive film to be formed on underwtanding fresh surface, following grinding, machining etc. Crevice corrosion is commonly found in crevices where oxygen is restricted and in low pH environments like sea water.

The Accreditation Scheme criteria requires all fabricators to conform to stringent standards of competence, training and education, personal and professional conduct, adhering to a Code of Ethics and a Code of Practice, and committing themselves to continuing competency development. Installation Stainless steel is best installed last to avoid damage during construction.

Prevention would be better. She has been writing professionally since and has used her knowledge of programming, Web development and auto repair to share in her writing what she learns from her day-to-day adventures.

Stainless Fabrication: Common Traps to Avoid

Designing Building Exteriors in Stainless Steel. The anode end of a battery is corrosive, while the cathode end is passive and no corrosion occurs.

Welding The high temperature characteristics of welding can introduce surface and other defects which must be addressed. A general introduction to stainless steel for architects, including grades, standards, properties of stainless uneerstanding, EN specifications, surface finishes, environmental benefits and where to obtain further advice.

The Scheme gives owners and specifiers of stainless steel greater certainty that fabrications using stainless steel will be performed by technically competent industry specialists. It is also important to remove any zinc that might be present.

Specifying Stainless Steel for Architectural Applications. This chromium layer is Angstroms — or millionth of a centimeter — in thickness according to WorldStainless. Oil, grease, fingerprints, crayon, paint and chalk marks may also contain products that can provide crevices for localised corrosion and also act as shields to chemical and electrochemical cleaning.

Distortion Stainless steel has a relatively high coefficient of thermal expansion coupled with low thermal conductivity, at least compared with carbon steel. Design, construction and technology. Residual adhesives from tape and protective plastic sometimes remain on surfaces when they are stripped. The Place to Start What Is Tungsten Steel?

BSSA Understanding Stainless Steel “Centenary Edition”

Organic solvents should remove soft adhesive particles. Passivating, unlike pickling, will not cause a marked change in the appearance of the steel surface. Clean abrasive disks and steep flapper wheels are commonly used to remove heat tint and other minor surface imperfections.

A common misconception is that stainless steel is percent corrosion resistant as explained by eStainlessSteel. Copyright Leaf Group Ltd. Mechanical Cleaning Wire brushing should only be done with stainless steel bristles that have not been used on any other surface but stainless steel. Nitric acid treatments will remove free iron, but not iron oxide contaminants. The Superduplex steel offers a slight improvement with 45 percent at room temperature. Galvanic corrosion happens when two different metals are placed in an electrolyte environment; the cathode removes metal from the anode.

The protective film reforms after exposure to air. Duplex Steel is more resistant as the heat rises.

BSSA Guide to Understanding Stainless Steel | Steel Times International

Deleterious oxides of chromium may develop on each side and on the under surface of welds and ground areas. Selective leeching is a type of corrosion wherein a fluid will simply remove metal during demineralization or deionization. Erosion is caused by an abrasive fluid flowing past a metal at high velocity, removing its protective layer. Depending on which text editor you’re pasting into, you might have to add the italics to the site name.